856-324-0165

ADVANCED BIOLOGICAL WASTEWATER TREATMENT

BioGill® manufactures above ground, attached growth bioreactors that deliver compact and affordable wastewater treatment solutions. Our team of production and engineering professionals ensure our Biogill systems deliver for our customers site requirements and treatment expectations.

BioGill is a biotechnology company that brings together the power of science and nature to improve the quality of wastewater for a healthier environment. They design and manufacture above-ground, attached growth bioreactors that deliver highly effective,

low cost and energy-efficient water treatment systems. By combining simple, yet smart technology and natural biological processes, BioGill units are highly effective in

reducing organic loads in wastewater. Our goal is to deliver wastewater treatment solutions that are

great for the environment and good for the bottom line.

-

No Licensed Operator Required

-

Save on Energy Costs Year After Year

-

Avoid Surcharge and Hauling Fees

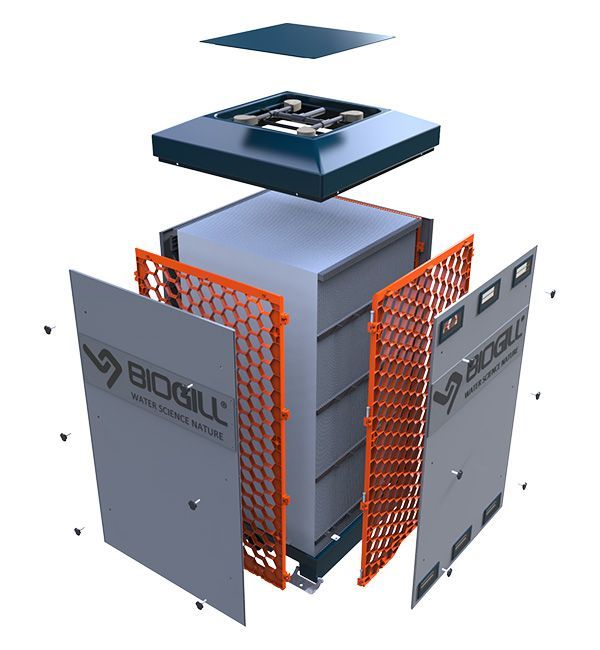

BioGill Ultra Tower (10 Treatment Cartirdges)

Stand-alone container sized system with two stage internal treatment tanks. Contains 10 internal treatment cartridges. Angled floor for easy sludge removal.

The BioGill® Ultra is the largest capacity bioreactor in the BioGill® product range. The Ultra is purpose built for small to medium Food & Beverage producers such as breweries and wineries with larger volume, high BOD & COD wastewater, as well as small to medium decentralized sewage systems.

The Ultra comes complete with a container housing ten internal treatment cartridges, a recirculation tank, pumps and control panel.

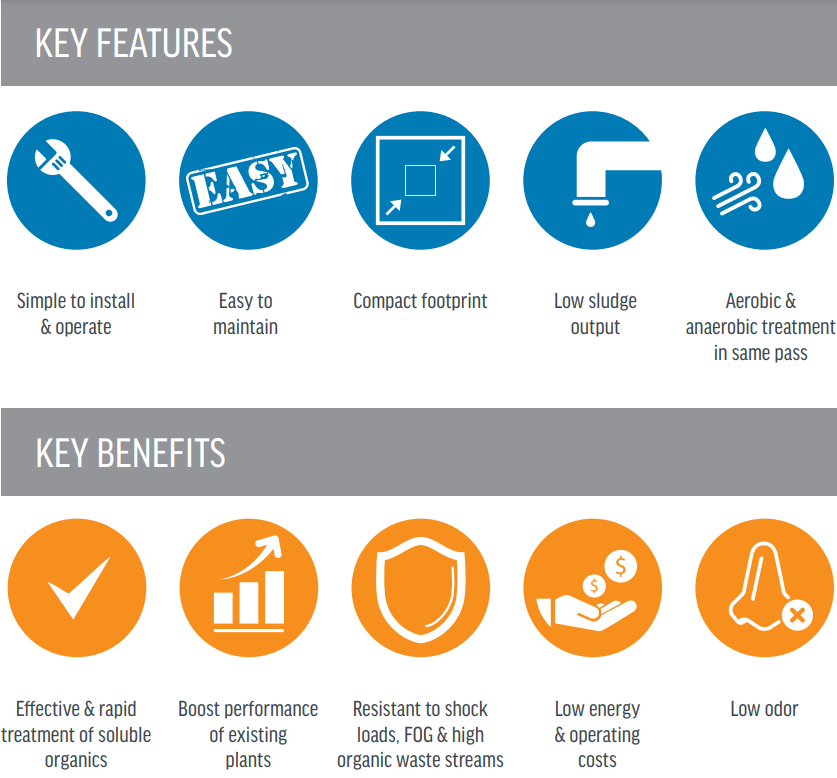

Key Features

- Simple to operate

- Low sludge yield

- Low energy consumption

- Modular and expandable

- Tolerance to high organic loading and FOG

- Tolerance to fluctuations in flow & load

- Rapid biological start up and restart time

- Quick installation

- Easy to operate with minimal operation input

- Simultaneous aerobic & anaerobic treatment

- Low life cycle costs

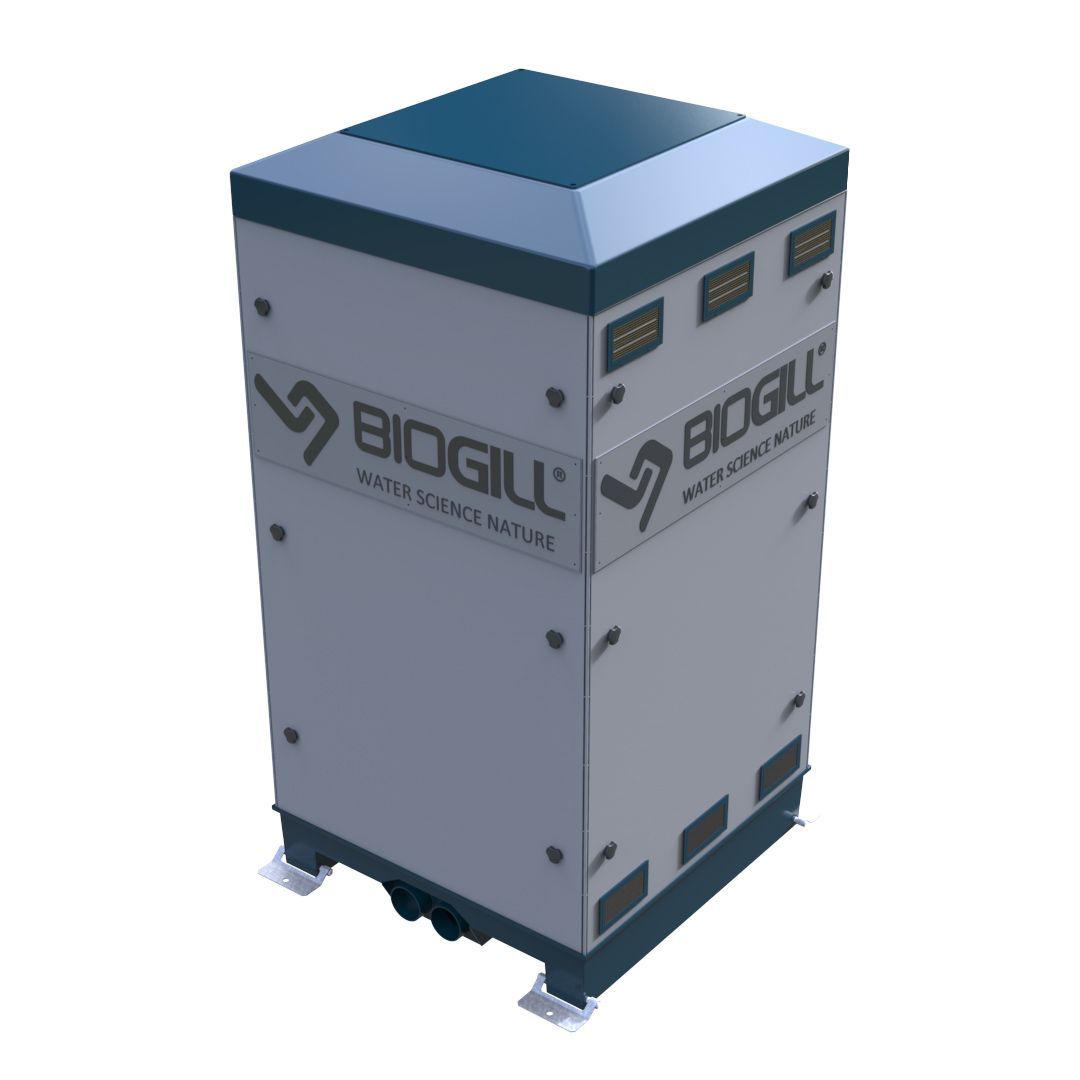

BioGill Tower (Single Treatment Cartridge)

Simple to install, easy to operate with minimal maintenance requirements, this unit is ideal for Food and Beverage producers such as breweries and wineries with low volume, high BOD wastewater. The BioGill Tower can also be used for small scale municipal and decentralized sewage treatment. This is the smallest bioreactor in the BioGill range, designed to fit tight spaces or be raised on a platform to reduce the footprint. The unit is ideal too as a performance and capacity boost to an existing wastewater treatment plant.

Key Features

- Quick to install

- Simple to operate

- Easy to maintain

- Hydroswirl manifold – Patented wastewater distribution system

- Compact to fit tight spaces

- Modular and scalable

- Highly effective at reducing organic loads and BOD

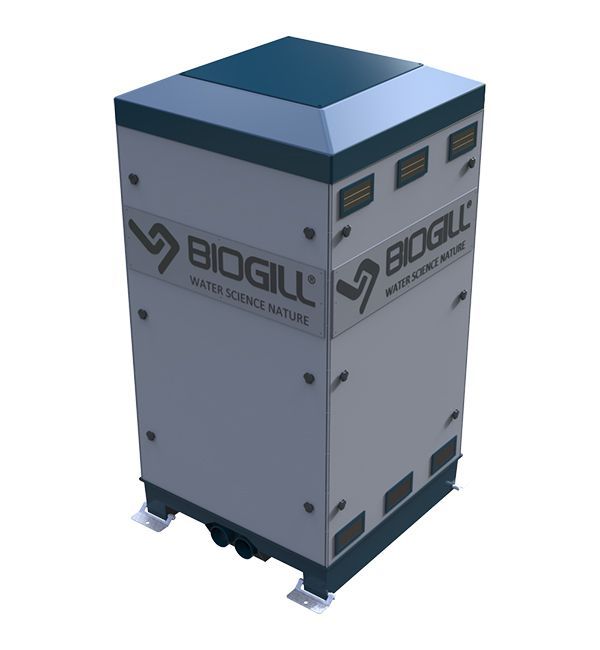

BioGill Max 2

New from Biogill the Max 2 delivers an affordable and compact simplified biological treatment solution for industrial strength wastewater that can easily be operated and installed in smaller plants.

Key Features

- Quick to install

- Simple to operate

- Easy to maintain

- Hydroswirl manifold – Patented wastewater distribution system

- Compact to fit tight spaces

- Modular and scalable

- Highly effective at reducing organic loads and BOD

- Two stage treatment option

- Durable stainless-steel construction

BioGill Max 4 (4 Treatment Cartridges)

The BioGill Max Series is an attached growth bioreactor for secondary/ biological wastewater treatment. The Max 4 packaged system is a compact design to fit most plants, producing a wide range of wastewater volumes seeking a simple, robust and highly efficient biological treatment system or for adding capacity to existing wastewater treatment systems.

Key Features

- Durable stainless-steel construction

- Simple to operate with minimal control complications

- Quiet operation with submersible pumps

- Low sludge yield

- Low energy consumption

- Tolerance to high organic loading and FOG

- Tolerance to fluctuations in flow & load

- Rapid biological start-up and restart time

- Quick installation

- Low maintenance

- Simultaneous aerobic & anaerobic treatment

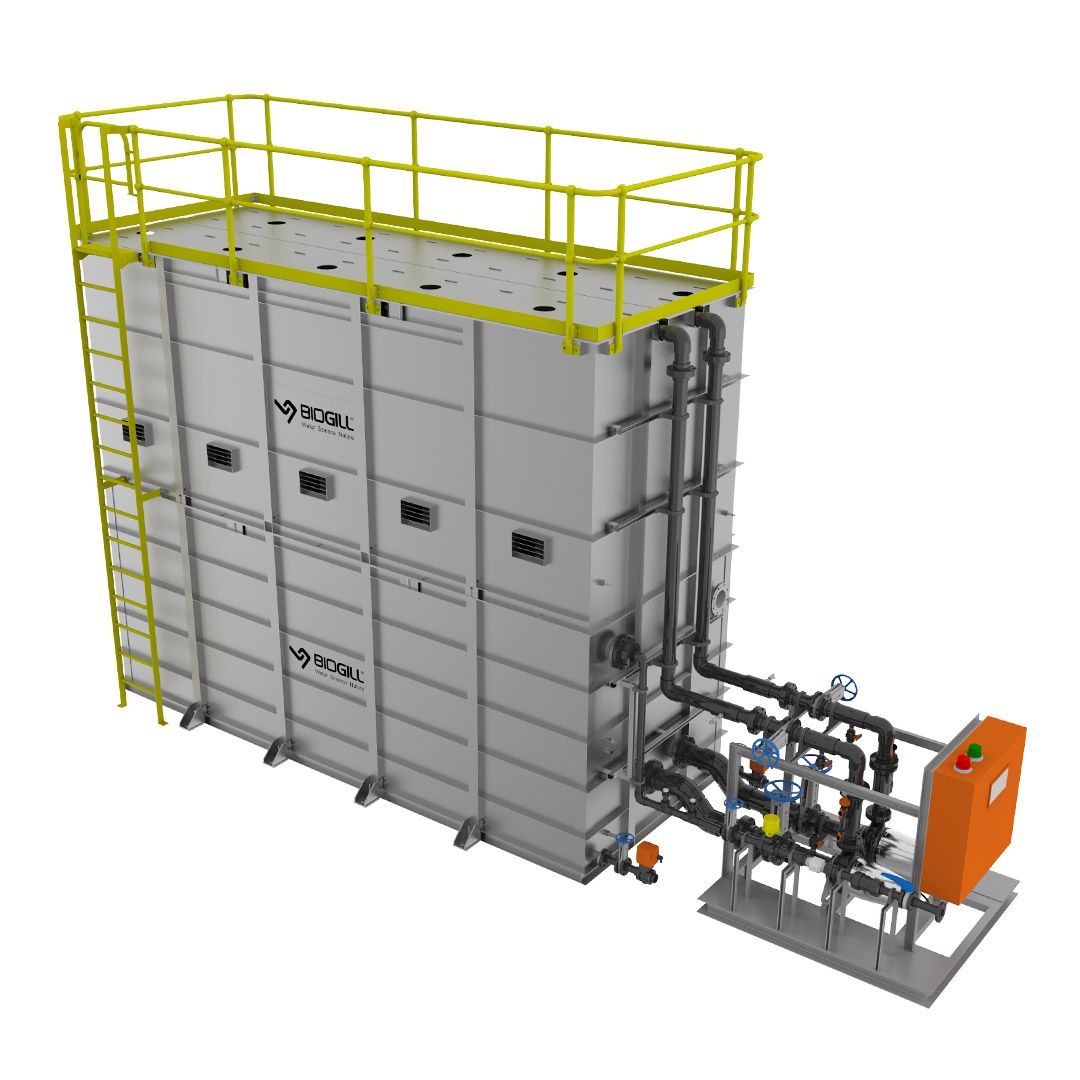

BioGill Max 6 (6 Treatment Cartidges)

BioGill Max Series units can be arranged in single and multi-unit configurations to meet a wide range of flow, loading, and removal requirements. Systems are easy to expand through the addition of units.

The BioGill Max 6 comes complete with a container housing 6 internal treatment cartridges, a recirculation tank, recirculation pumps and control panel. The design is both compact and flexible, allowing for a variety of installation configurations.

Key Features

- Control system including PLC

- Two stage treatment unit

- Patented, non clog HydroSwirl™ water dispersal system

- Safety rail & ladder (optional)

- Durable stainless-steel construction

- Simple to operate with minimal control complications

- Quiet operation with submersible pumps

- Low sludge yield

- Low energy consumption

- Tolerance to high organic loading and FOG

- Tolerance to fluctuations in flow & load

- Rapid biological start up and restart time

Main Office

1101 Kings Hwy NSuite 308Cherry Hill, NJ 08034

Request a Quote

Contact Us

We will get back to you as soon as possible.

Please try again later.

Contact

Manager - Matt Gurkin

mhartco@comcast.net

Phone: 856-324-0165

Fax: 856-324-0176

- Mon - Fri

- -

- Sat - Sun

- Closed

Subscribe to Our Newsletter

Newsletter Signup

We will get back to you as soon as possible.

Please try again later.